DTG is different in this means and instead the ink shall be utilized as a single skinny layer. Round 2 goes to the champ, who edged out the newcomer with its dark garment capabilities. When deciding between digital printing on fabric and display screen print in your subsequent attire run, its important to understand the distinctive benefits each has to supply. As know-how advances, the gap between these two strategies will narrow.

Our Camo Printed/ Allover printed Garments are either 100% Cotton Fabric Surface or Cotton/Polyester blend cloth surface with a water primarily based camo/allover print. Mesh rely will depend on design and may range job to job, color to color. Curing temperature around 320+ for plastisol and discharge, round 300 for water base. Again these rely upon individual dryers as well as the amount of inks used. Plastisol, Waterbase, and Discharge inks work well relying on design and color of garment.

To get extra technical, it is a frequency-modulated halftone instead of an amplitude-modulated halftone. [newline]It can typically result in a grainy look, however a significantly better reproduction of small particulars. For greatest results submit a high-resolution digital artwork file at desired ultimate measurement of output at 300dpi to completed dimension, or absolutely vector format with all fonts outlined . Laser etching is a superb new service we’ve added for leather-based, glass, thermos, and wood. With this machine, we will present custom leather-based patches that our Embroidery Department can then sew onto your clothes.

It can also be used to cut our Tackle Twill for applique, and vinyl for jersey personalizations with impressive precision, and no frayed edges. Hot peel transfers look semi-glossy, semi-matte because when you lift off the film, it lifts somewhat of the ink with it, which breaks up the surface. Jerseys, hoodies, and so on. usually have sheets of plastisol layered on high of one another. Therefore, athletic attire is dtg tshirt printer vs screen printing rather more shiny compared to different kinds of attire. Laying down a heavier ink deposit may also make a print look glossy.

If you select a DTG-only service, the price per shirt does not lower when you buy more, while in general, you pay much less per shirt as the quantities enhance during display screen printing. However, the intense means of changing the design into a number of fashions limits the number of colors that can be utilized. DTG printing produces a barely faded design with a single layer of ink, however with out limits on the number of colors that can be utilized. However, there are some limitations that make sure shade combinations troublesome. DTG printing involves using a digital printer to apply ink instantly onto the material of the garments you might be customizing. This is a new method of printing t-shirts that has gained much popularity in current years thanks to the technological improvements of DTG printers.

Most corporations will provide strict brand tips that specify Pantone colors. If you’re severe about either technique, take a glance at the sections under to get a greater concept of the professionals and cons. As a matter of truth, the majority of on-line printing corporations similar to Redbubble, Society6 and Threadless are additionally now using DTG machines in their production line. This ends in a soft-hand, vibrant and permanent print that is sturdy and fewer vulnerable to fading and peeling. Aside from common colours, yow will discover metallic or glitter like vinyl to add some results on the garment. Heat press vinyl transfers are generally seen on sportswear like jerseys and monitor fits but can also be found on tote bags, coats, scarves, blankets, stuffed animals, and so on.

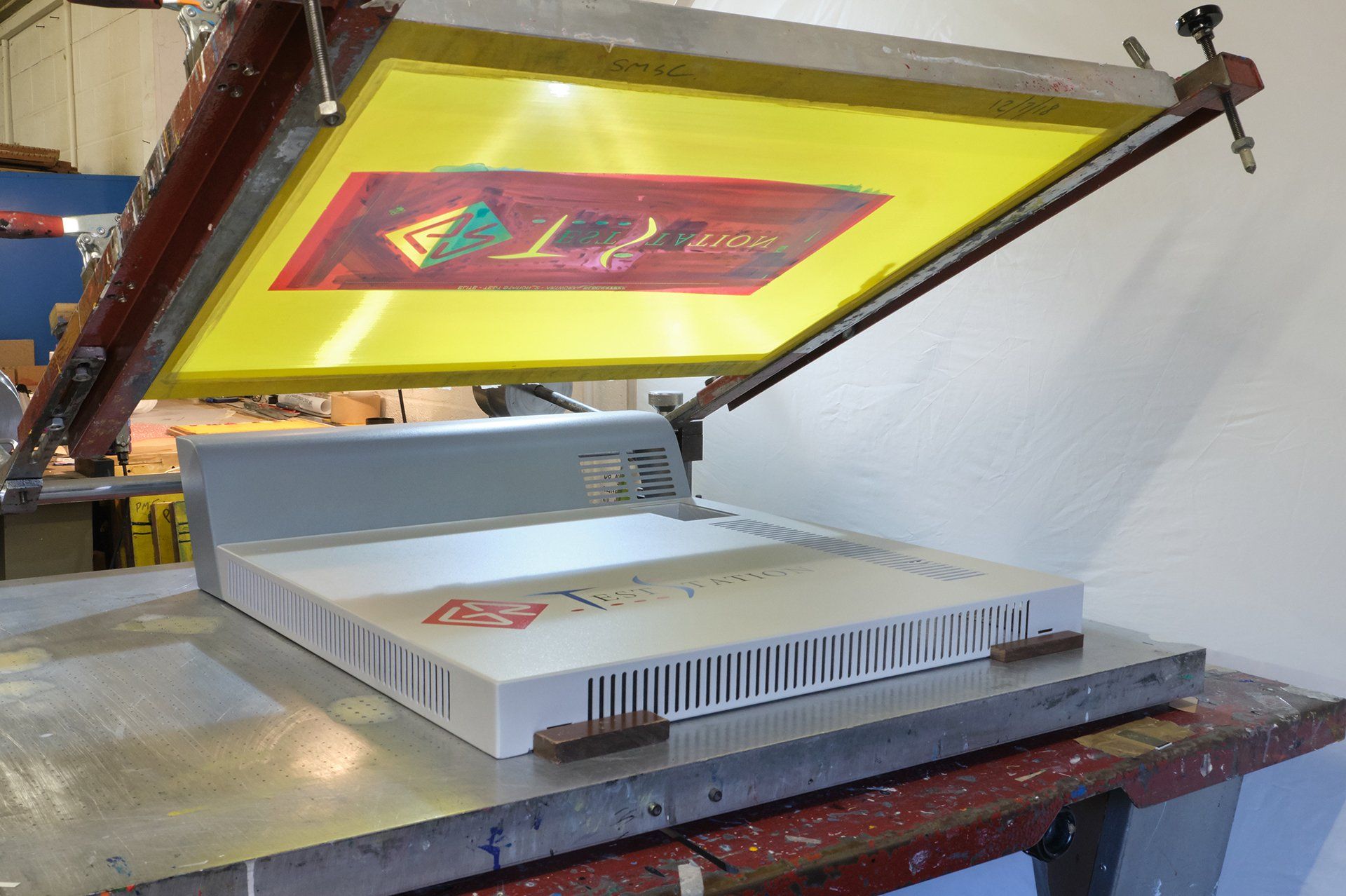

This means that your design must first be divided into several layers by colour. This is usually done utilizing design software program similar to Photoshop or Illustrator. Next, a template for braided screens is used to apply only one shade of ink at a time, a template for the colour used within the shirt design. In addition, keep away from carded open-end shirts as a outcome of they are going to be scratchy, heavy, and cheap. In most circumstances, you will also wish to use a lighter-colored background for the graphics in your DTG to really show up nicely.

When you print over these parts of garments, it creates a niche in the print the place the ink in the screen doesn't hit the shirt as a outcome of ridge caused by the seam. For this cause, we don't advocate printing over-the-zipper. Double Lined hoodies may be printed with 1 shade and no underbase. The additional layer of cloth doesn't allow for correct fastening to the press, which restricts us from a quantity of colours and tight registration. You can achieve versatility by including basic colors corresponding to white, black, or gray.

And due to innovative minds, you can now mass produce quality garments in report speeds. During the screen-printing process, the ink really becomes a half of the fabric versus a heat-pressed ink that simply sits on prime of the fabric. That’s why heat-transfers don’t maintain up as properly to machine washing and drying – they may crack and fade over time whereas display prints tend to hold quick and true. Screen printing is extra convenient for big batches of shirts. The template process implies that set up prices are barely larger, nevertheless it also makes screen printing for big orders of a design more environment friendly.

These inks are almost clear and are effective in full darkness, radiating shiny green shade. Special results printing is all about including that further pop and dimensions to a print. In terms of adding special results, DTG doesn’t stand an opportunity. While DTG is convenient, automated and pretty much a passive activity once you hit ‘print’. There are variables that are harder to regulate, to not point out dearer to repair e.g. clogged print head comes to thoughts. When talking about print sturdiness, we’re speaking about how lengthy the quality of the print lasts. Accurately matching colors is important, particularly by means of company branding.

Once the display is dry, the design is positioned on high of it and secured in place utilizing an adhesive. The elements of the display screen that haven’t been lined with the design will harden, while the remainder will remain soft. When the display screen is absolutely dry, the design can be removed utilizing a small brush and water.

A single move of gold and cream permits for the feel of the triblend to come back by way of. Adding a distressed filter on the artwork, even adds more to the classic really feel. While water-based inks are extra eco-friendly, but it’s not by much. Well, water-based inks also include plastic in the type of acrylics and different binders. They depend on solvents that evaporate, leaving the pigmented binder compounds on the clothes.

In display printing on attire, there are numerous strategies and two forms of inks which would possibly be commonly used, water-based inks and Plastisol inks. In this submit, we are going to compare the two and in the end offer you advice on the most effective ink for the kind of print you are trying to realize. There are many variations and similarities between these two methods of printing, and there are a variety of criteria to be taken into consideration when making your choice.

Additionally, hoodies are one of many tougher clothes to print on, however they're one of the most in style and best-selling types in the winter. Please pay consideration to the next issues that can happen when printing on hoodies and different fleece. Printing over the seam of a shirt trigger construct up and inconsistency as a outcome of UNEVENNESS on the seam. While this stable color print might cross as a enough print, other designs involving extra colour, element, or mixing, might have a worse effect. Here is an example between a white ink with a single move and a white ink with two passes.

That mentioned, DTG prints normally range from $12 to $15 per unit. If a direct to garment printed T-shirt is worn usually and closely laundered, it will begin to fade extra shortly than a screen-printed one.

However, recent developments have produced commercial grade transfer papers that are impressively vibrant and longer lasting. This makes custom screen-printed shirts a smarter selection to gather bigger funds or for events, like for 5K or a fundraising campaign for mission trips. Outlined listed under are some advantages and downsides of using DTG in your next custom T-shirt printing project. DTG is dependent upon cyan, magenta, yellow, and black colors to make different shades. The DTG is slow, it's highly detailed, and its designs are long-lasting. Also, since it's best for small productions, pace just isn't a crucial factor to suppose about.